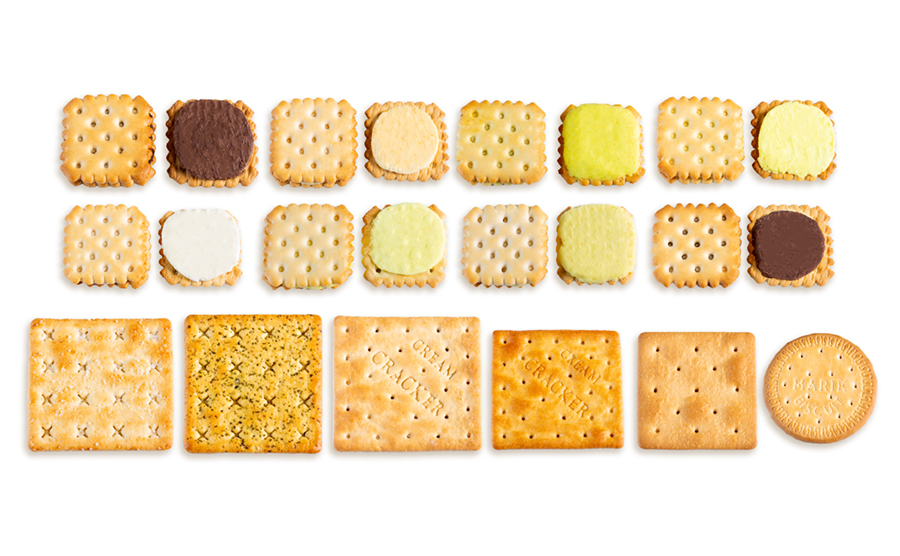

We are proud to say that our biscuits are made with high quality ingredients and it’s vegetarian.. We have been making biscuits for over 17 years and the consistency in taste and quality is what makes us stand out from other brands.

Lorem ipsum dolor sit amet gravida nibh vel velit auctor aliquet. Aenean

sollicitudin, lorem quis bibendum auci. Proin gravida nibh vel veliau ctor aliquenean.

+01145928421